Dear clients

DEFIS always innovates for you!

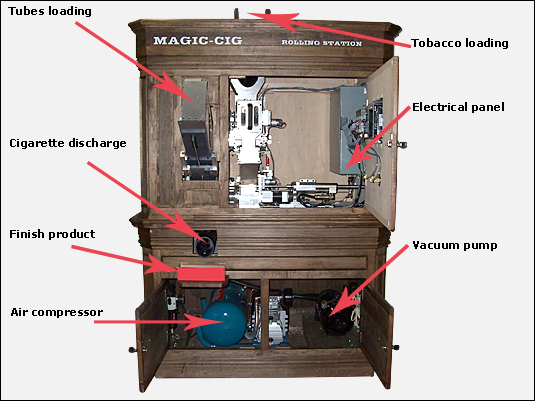

DEFIS developed a counter cigarette making machine that uses standard cigarette tubes. Customers carefully slide the tubes into the machine, and then put 200 grams of tobacco into the tobacco hopper. The Start Button is pressed and the machine produces fresh cigarettes at a low price, matching any customer tastes.

Small PLC controller provides a state of the art automat MAGIC-CIG® is a revolutionary and unique system to manufacture cigarettes

|

Machines’ advantages and particularities

Many reasons explain the popularity of Groupe DEFIS’ products. The cigarettes are fresh and manufactured according to customers’ needs. They can choose their tubes, tobaccos, as well as the compaction degree. The machines are generally installed in big urbanized centres, close to customers, therefore facilitating customer retention.

Nowadays, manufacturing cigarettes does not require a factory equipped with expensive ambient air control systems, sophisticated machines, and expensive manpower or syndicated employees.

Installing machines in various areas of a metropolis is suitable to serve a target market. Some users only manufacture “cigar imitation” or flavoured cigarettes. These cigarettes are sold at a very high price, either by snobbery or simply in accordance with customers’ likings.

The exploitation fees of the machines are insignificant. The machines are connected into a residential outlet of 115 or 220 volts, according to countries. With these machines, customers are sure to get fresh, natural and additive free products, a little like the coffee grinding machines we find in certain food chains. While the machine automatically produces cigarettes, some merchants offer their customers a coffee, present them a promotional video or let them do their shopping.

Knowing well the habits of their customers, others prepare the cigarettes in advance.

Machine users do not have to compound with cigarettes suppliers who impose their selling conditions and, sometimes, the market laws. Every machine can be manipulated to fit in narrow passages, like residential doors. Generally, two people can move the machines, which are assembled on rollers.

The technology

There is no similar machine on the market: the concept is unique.There are electrical or hand machines, that smokers use at home for their personal needs. Groupe DEFIS’ machines are rather destined to commercial or even semi-industrial markets.

The machines’ equipment and diverse machine-made parts are conceived and manufactured with the best of care, according to the rules of art, based on a 30 years experience in machinery construction for aircraft, pharmaceutical, food and other industries.The machines’ material and various components are carefully selected, according to the highest quality standards.

Electrical, electronic or pneumatic parts used for the production of the machines are standard and available on the world-wide market.The cigarette production concept is unique and patent pending. All of the equipment manufactured by Groupe DEFIS can run 24 hours a day, seven daysa week. However, it is recommended to clean them on a daily basis. This operation only requires a few minutes.

The standard equipments of the machine are suitable for producing king size cigarettes. The length of the filters and tubes can however vary from +/- 3/8 inches, or approximately 10 mm, depending on supply sources.The modules of the tobacco preparation must be changed in order to produce longer cigarettes.

No blocking or unjustified interruptions

Thanks to the new technology, cigarette manufacturing machines are highly reliable. They can produce cigarettes without interruption. Deformed tubes, which have unfortunately been misplaced in the machine, are ejected by an air jet, thus preventing any blocking. The machines are programmed to interrupt all activity after three consecutive stops, for example, if the tubes are damaged or if the tobacco is to damp. The machines are equipped with an automatic cleaning cycle, which activates at the end of the production. They also have a starting cycle to rapidly load every element in order to produce good cigarettes.

Fabricated according to construction standards

The machines are fabricated in conformity with packaging machine construction standards. Groupe DEFIS can also conform to particular standards in force in certain countries.

The market

The tendency in the general market favours the use of our machines in tobacco stores. Customers produce their own cigarettes, purchasing their tubes and tobacco in tobacconist shops. They can sell tobacco products in bulk and not cigarettes, which allows them to bypass laws and the cigarette taxation system in force in some states.

The owner of the machines collects an amount to its customers. Customers therefore produce their own cigarettes, and there is no labour taxe. Nowadays, there is a wide opening of the African, Asian, European or South American markets.Even if, in these countries, the cost of a pack of cigarettes is often derisory, producing cigarettes using semi-industrial machines is still advantageous, because the cost of raw materials is proportional to the selling price of finished products. The investment return for the buyers is very short and varies according to the machines usage (from 6 to 8 weeks, depending on the selling price of the cigarettes and the number of usage hours).

Our clientele

Our main customers live in Pakistan, India, Mexico, Central and South America, Morocco, Algeria, etc. For the present, Groupe DEFIS does not accept orders from Asian countries, but is rather looking for buyers interested in buying copyrights to manufacture the machines in their designated countries. These buyers must protect their market from plagiarism and insure post purchase service on their territory. The parties will sign non-competition and loyalty clauses, aiming at developing a solid and transparent partnership. Most customers have our old technology, which is still very reliable. Last November, Groupe DEFIS sent its first new machine to Seattle, to a bulk distributor, who will insure the commercialisation of the Magig-Cig-25 model in the United States, mainly in tobacco stores.

Most customers want to remain anonymous for various reasons: anti-tobacco groups’ pressure, governmental sells controls, environments more or less controlled by groups claiming territory exclusivity, family values or illicit uses, of which Groupe DEFIS has no knowledge, etc.

The competition

Group DEFIS does not really have competitors, as similar machines do not exist.

There are rapid and sophisticated industrial machines, requiring specialized manpower and sold at a clearly higher cost. Different, the cigarette fabrication process of the competition favours the rolling method, which consists in using a paper strip wrapped around the tobacco, the filter being pasted on the cigarettes’ tips. Coming from certain Asian or Latin American countries, these machines are often fragile and capricious. Moreover, they require specialized manpower to run.

Machines’ particularities

All our models are built on a well-tried, reliable and durable guiding principal. Most of the parts are interchangeable, modular, normalized and standardized equipments. The main parts are highly precise, with an unparalleled finish and hardness, in order to ensure the quality, resistance and durability of the machines. Since the machines are based on a modular fabrication, they are easy to assemble, and their various modules are easy to reach. Different types of safety barriers can be added conformingly to customers’ needs. Covering can be made of steel, representing a cigarette shape, Lexan panels or in wood like nice cabinet with many access doors to the machines’ various sections.

Easiness for the operators

Operating the machines is a child’s game. After a few hours of training, operators master all the programs and operation or maintenance modes of the machines. A touch screen displaying messages guides them in the choice of options or productions.

Tobacco by-products

The machines can also be used with products as diversified as herbs, in replacement of the tobacco. Certain herbs are non-toxic and nicotine free. The leaves or herbs must be in the form of filaments of ¼ inch and ½ inch, or 6 and 12 mm, which suits perfectly the cigarette fabrication process. The humidity level of the tobacco or other related products must be between 14 and 16%. This level can be lesser with no harm to the machines. However, dry products may not stay compressed in the cigarettes’ tubes.

Environment and ambient air

The machines do not require a particular environment. The ambient temperature of a house will not influence their operations. However, it is recommended to avoid very dry humidity levels in order to prevent the creation of static electricity. A simple small residential humidifier is suitable if the house is equipped with an electrical air heating system.

No maintenance

The mechanisms used to produce cigarettes are conceived and fabricated according to the rules of art. Their life span is about 25 years. Users must respect the manufacturer’s orders concerning cleaning and maintenance. The choice of the pneumatic components is guaranteed for millions of cycles. The controls and electronic parts do not wear down, but can however be replaced, if need be or at the time of a normal breakdown. They are available in every industrialized country, through the manufacturer. Most components used in the machines are standard products on the market.

Taxes and laws in force in the countries

According to the laws in force in their country at the time of the transaction, customers must conform themselves to perceive excise taxes on tobacco and selling taxes of the product. It is highly recommended that future distributors inquire on the laws in force in their country. Groupe DEFIS can, in no case, be held responsible for any legal omission on the part of its customers.

|